Введение

The VCR (Metal Gasket Face Seal) Fitting is used in high-purity gas or liquid delivery systems and is widely applied in various industries such as Semiconductors, Hydrogen Energy, and Нефть и газ. Although it has a different name from VR, the essence is the same. Let’s take a look at the connection introduction of the VCR Fitting:

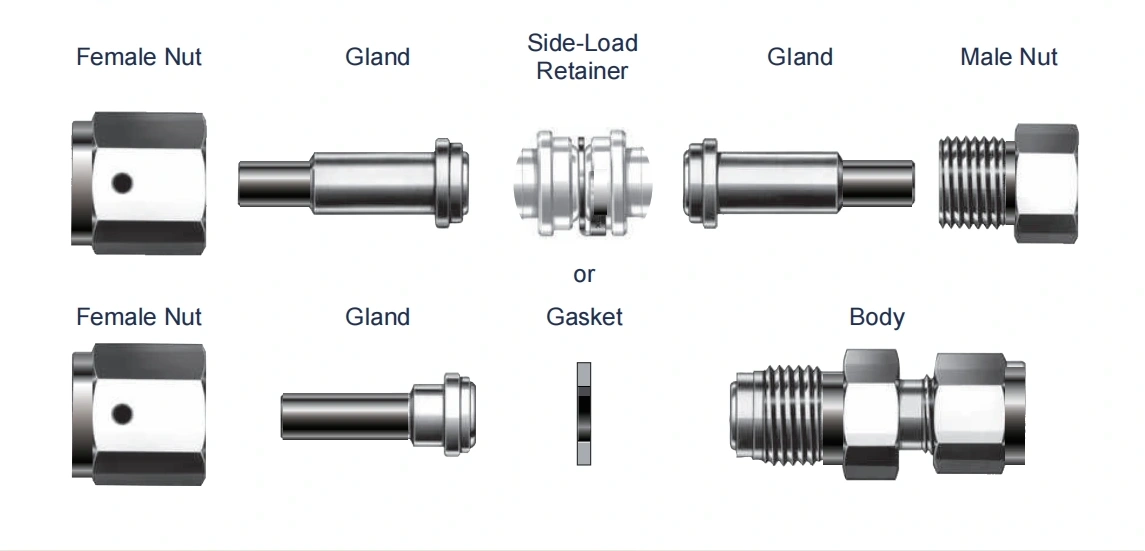

No.1—Main components of VCR Fitting

Body: Usually made of materials with good corrosion resistance and mechanical strength (such as stainless steel), the body features threads, flanges, or other connection methods for connecting with tubes or equipment to ensure compatibility and stability.

Gasket: Typically, metal gaskets are used, such as copper or stainless steel gaskets, or other materials that are high-temperature and corrosion-resistant. The gasket’s function is to provide a seal during the connection to prevent gas or liquid leakage.

Nut: Used to tighten the fitting, pressing the gasket firmly between the body and the connected object to ensure sealing performance.

Gland: The gland cooperates with the gasket to create a seal that prevents the working medium (such as gas or liquid) from leaking from the fitting.

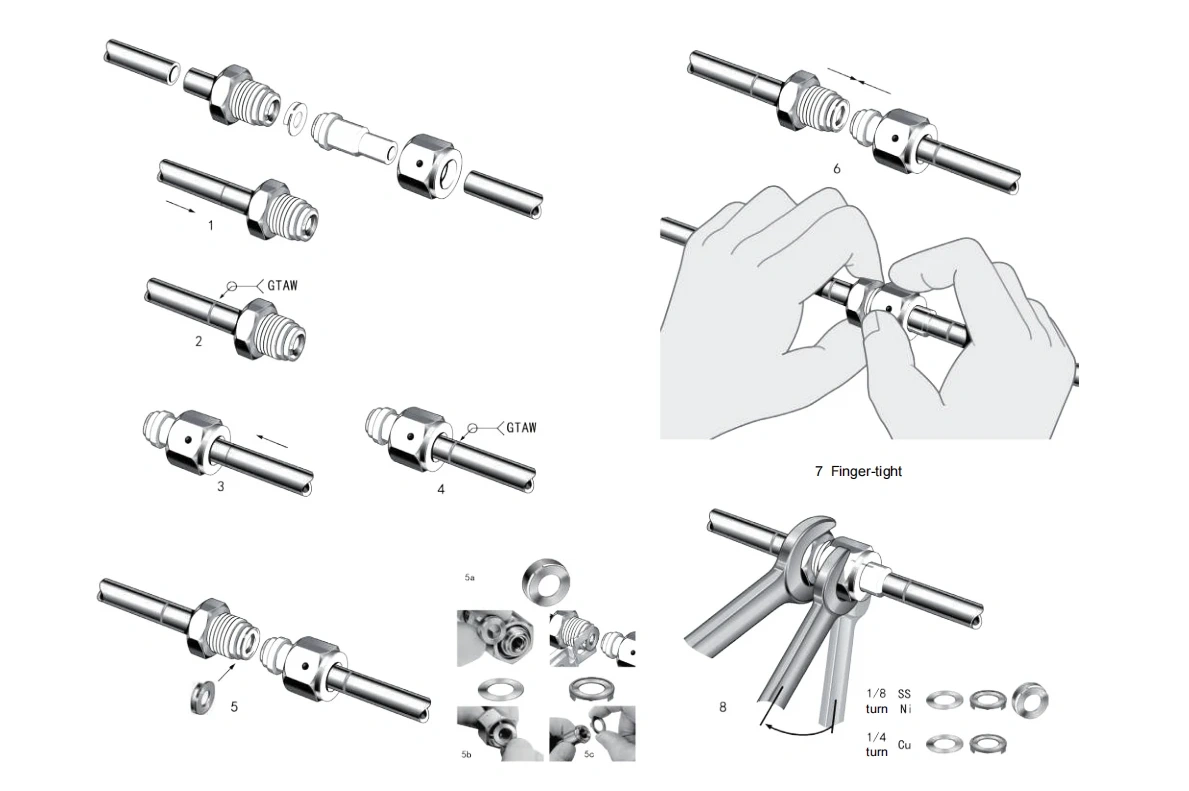

No.2—Connection Steps of VCR Fitting

Preparation:

Check whether the sizes of the fitting and the gland match to ensure the reliability of the connection.

Clean the connection parts of the fitting and the gland, removing impurities such as oil, dust, etc., from the surface to ensure the sealing effect.

Prepare the necessary tools, such as wrenches and torque wrenches.

Installation of Gaskets:

Place the gasket on the sealing surface of the fitting body, ensuring that it is in the correct position. The gasket should be flat, undamaged, and completely fit the sealing surface.

Connecting Glands:

Insert the gland into the fitting body, ensuring that the insertion depth meets the requirements. Generally, the gland should be inserted into the fitting body to the marked line or specified position.

Gently tighten the nut by hand to initially fix the fitting onto the gland.

Tightening the fitting:

Use a wrench or torque wrench to gradually tighten the nut according to the specified torque value. During the tightening process, apply force evenly to avoid deflection or over-tightening.

Check for any leakage at the connection. You can use a leak detection instrument or apply soapy water for testing. If leakage is found, stop the operation immediately, check the cause, and address it.

No.3—Precautions for VCR Fitting connection

Choose the Right Gasket:

Different working media and pressure levels require gaskets of various materials and thicknesses. Select the appropriate gasket based on actual conditions to ensure sealing performance.

Control the Tightening Torque:

Over-tightening the nut may damage the gasket or deform the fitting, thus affecting sealing performance. Tighten according to the specified torque value to avoid excessive tightening or loosening.

Avoid Impurities: During the connection process, ensure that impurities do not enter the fitting. Impurities can damage the gasket, affect sealing effectiveness, or even lead to system failure

Regular Inspection and Maintenance:

VCR fittings should be regularly inspected and maintained during use to ensure the reliability and sealing performance of the connection. If leakage, looseness, or other issues are found, they should be addressed promptly.

Заключение

The connection of VCR fittings must be carried out strictly according to operating procedures to ensure reliability and sealing performance. During use, attention should be given to selecting the right gasket, controlling the tightening torque, avoiding the entry of impurities, and conducting regular inspections and maintenance.

Если у вас возникли вопросы, пожалуйста связаться с нами напрямую, и мы свяжемся с вами в ближайшее время.