About KAVYA Group

KAVYA is a professional supplier in manufacturing and supporting industrial fluid systems. We have been driven by a passion for quality and a steadfast commitment to meeting customer needs, helping diverse industries move liquids and gases safely, efficiently, and reliably in challenging applications.

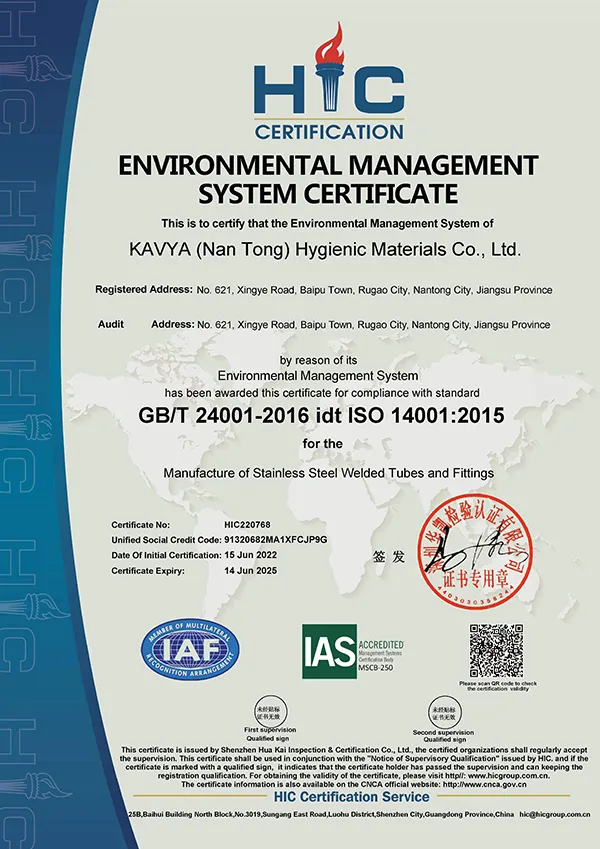

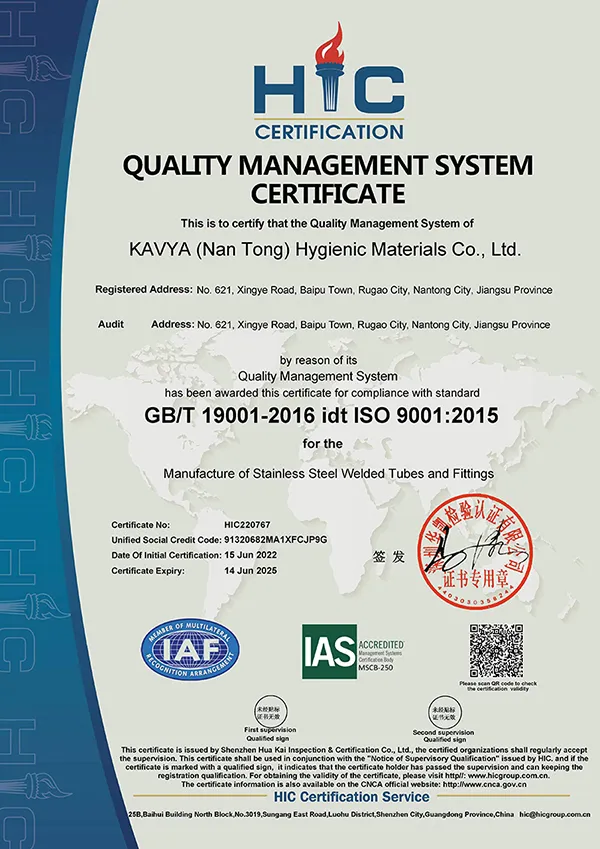

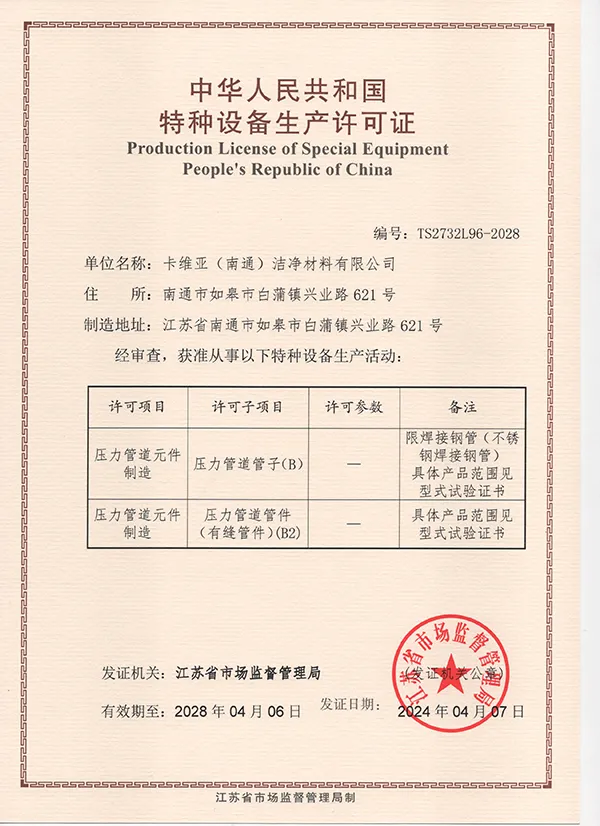

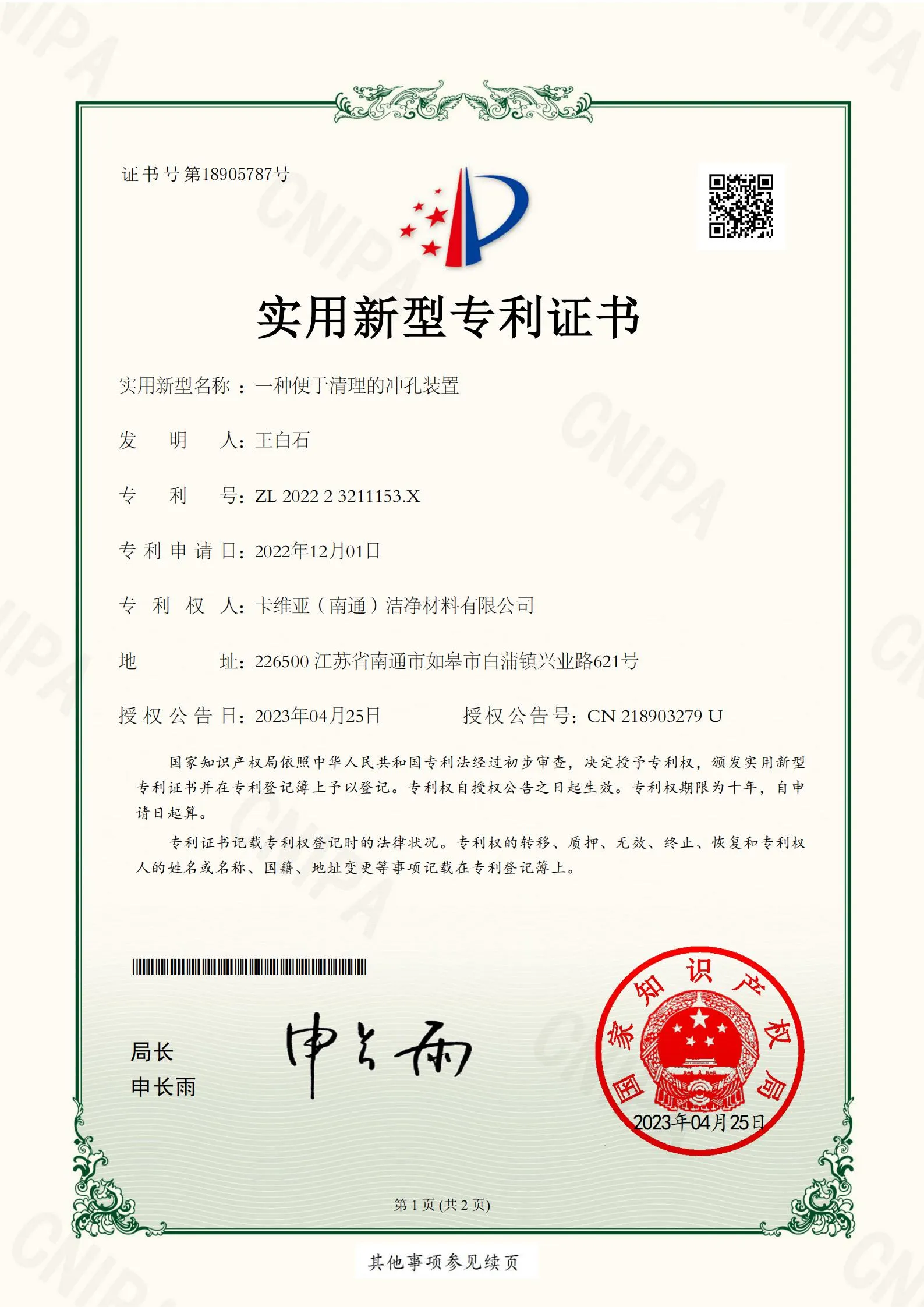

KAVYA Group was founded by the shareholders with more than 35 years’ rich experience in high purity and ultra-high purity tubing, fittings, valves, regulators industry from Taiwan. We have self-built modern factory of more than 11,000 square meters. As a member of International Semiconductor Association (SEMI), we have certificates such as TS, ASME BPE, 3A, ISO9001, ISO14001, ISO45001 etc.

Our mission is to enhance industrial operations through innovative products and exceptional service. We are committed to maintaining the highest standards of quality and performance in all our offerings, ensuring that our clients receive solutions they can trust.

Discover the Value of KAVYA Group

Precision in High Purity Manufacturing

At KAVYA, we specialize in producing high-purity and ultra-high-purity valves, fittings and tubing, ensuring that every product meets the stringent demands of the electronic semiconductor, food, and biopharmaceutical industries.

Unmatched Quality for Critical Applications

Our products are designed for environments where quality and reliability are paramount. Whether in cutting-edge semiconductor manufacturing or sensitive biopharmaceutical processes, KAVYA delivers components that perform flawlessly.

Innovative Solutions for Advanced Industries

KAVYA’s expertise in high-purity fluid systems supports the most advanced industries. Our state-of-the-art technologies and commitment to innovation help our clients achieve optimal performance in their critical applications.

Commitment to Excellence and Service

Beyond just products, KAVYA offers unparalleled support and service, ensuring that our customers can rely on us for both technical expertise and exceptional customer care in every project.

Manufacturing Line

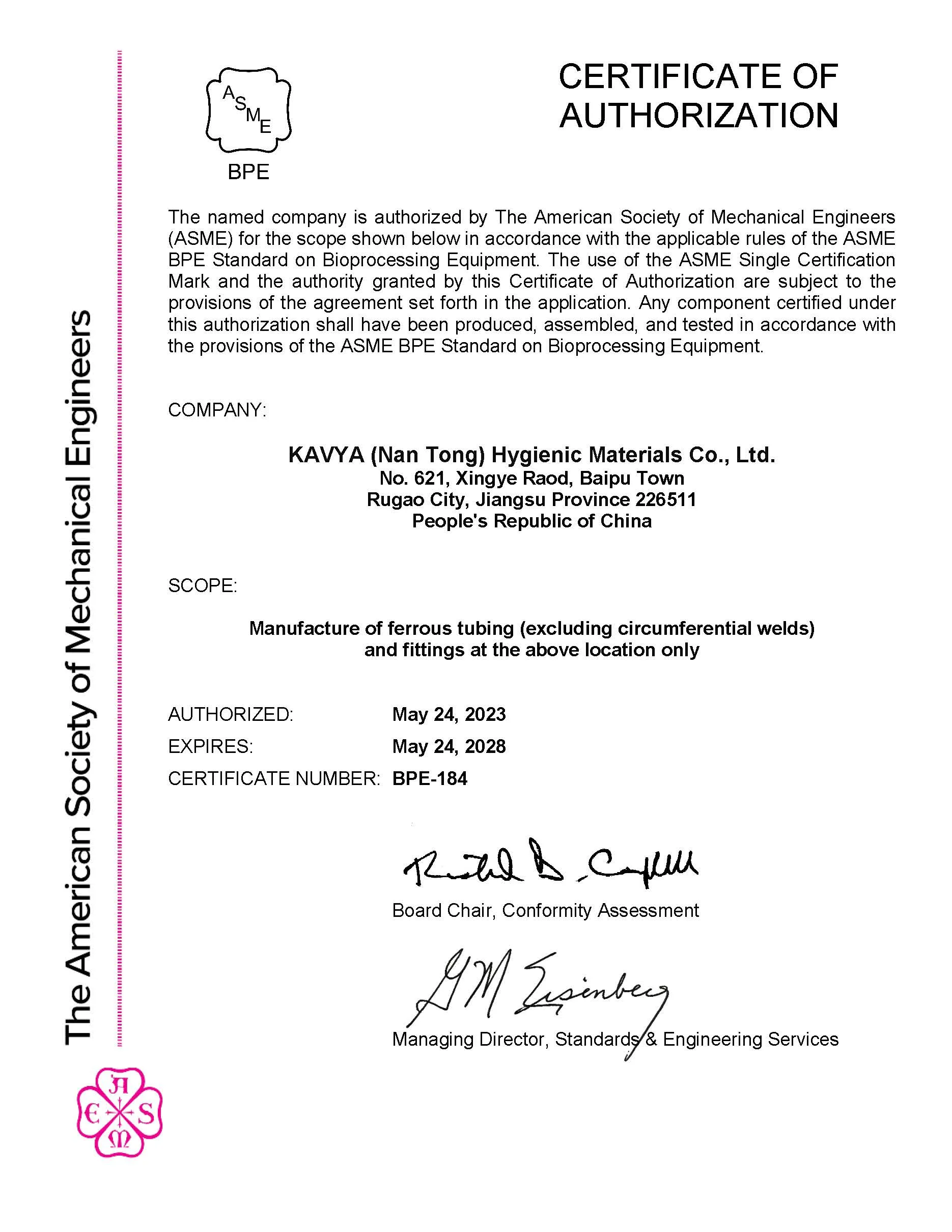

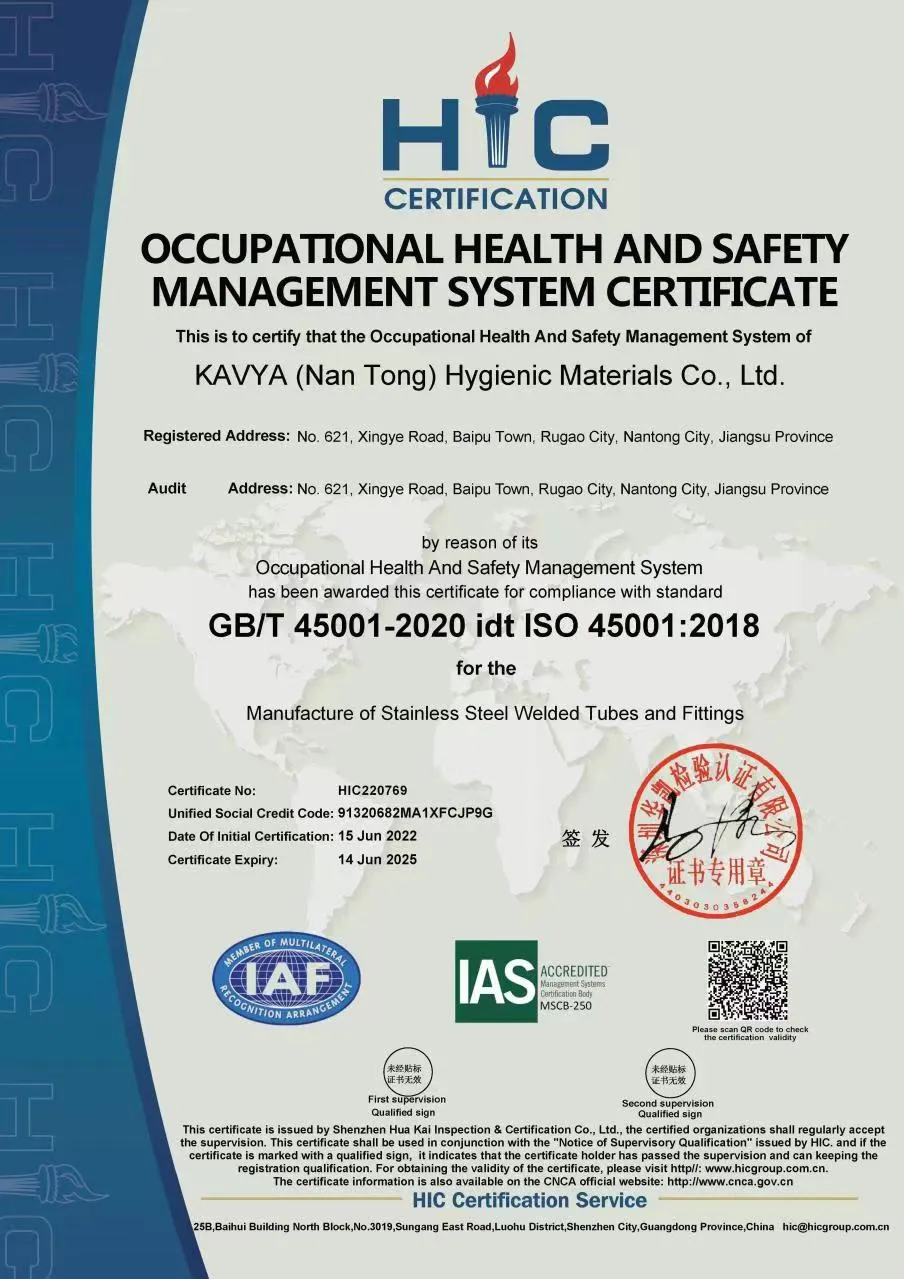

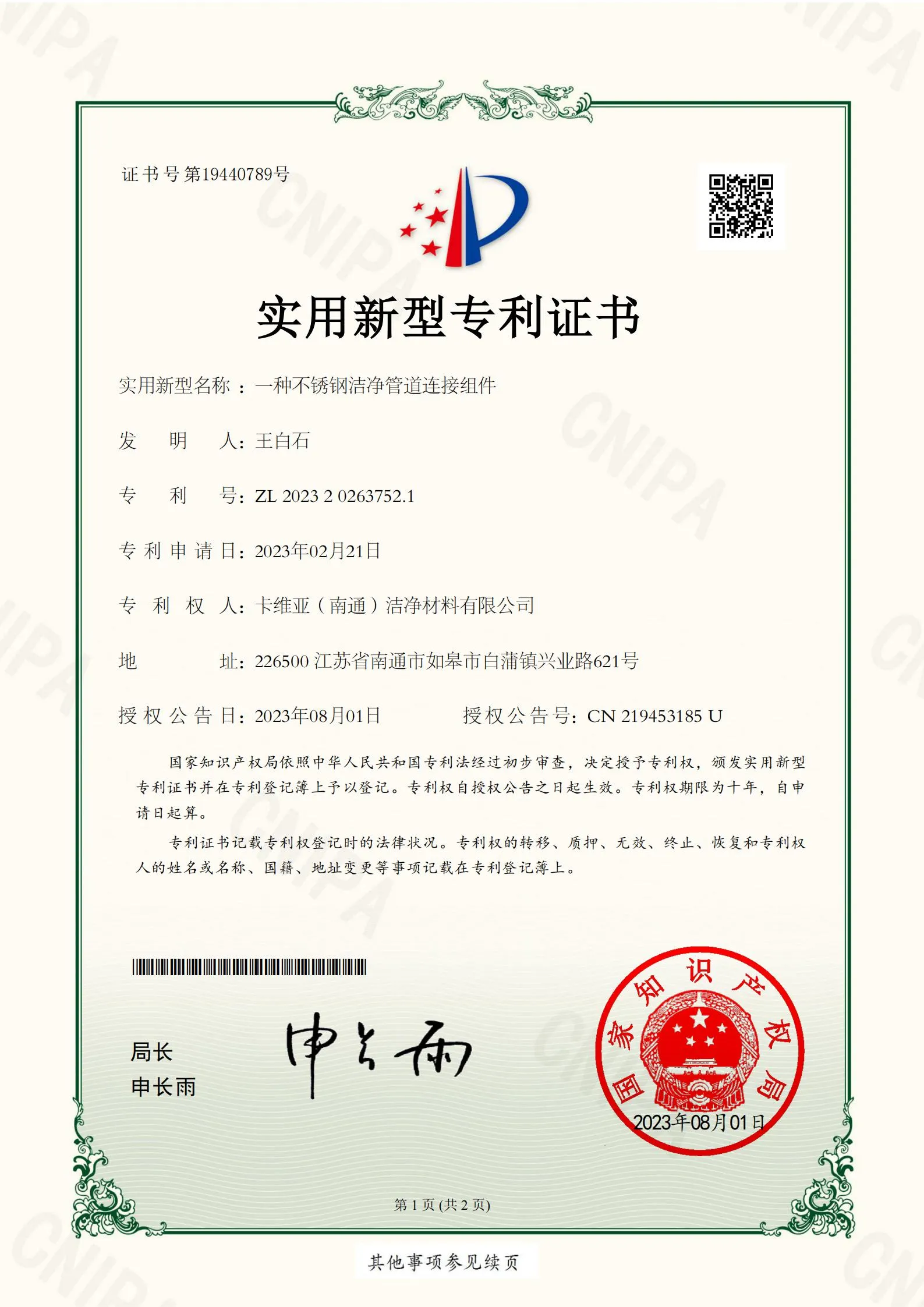

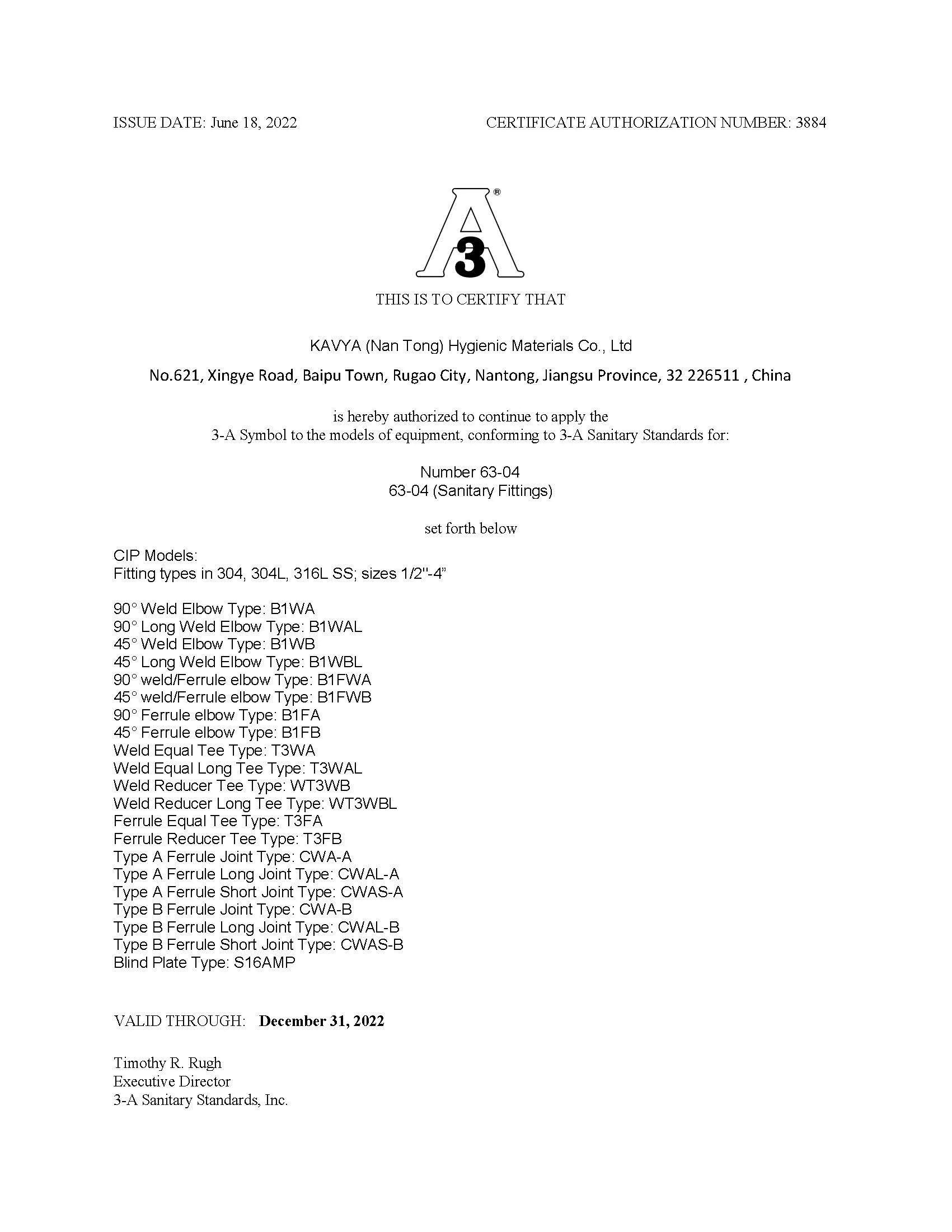

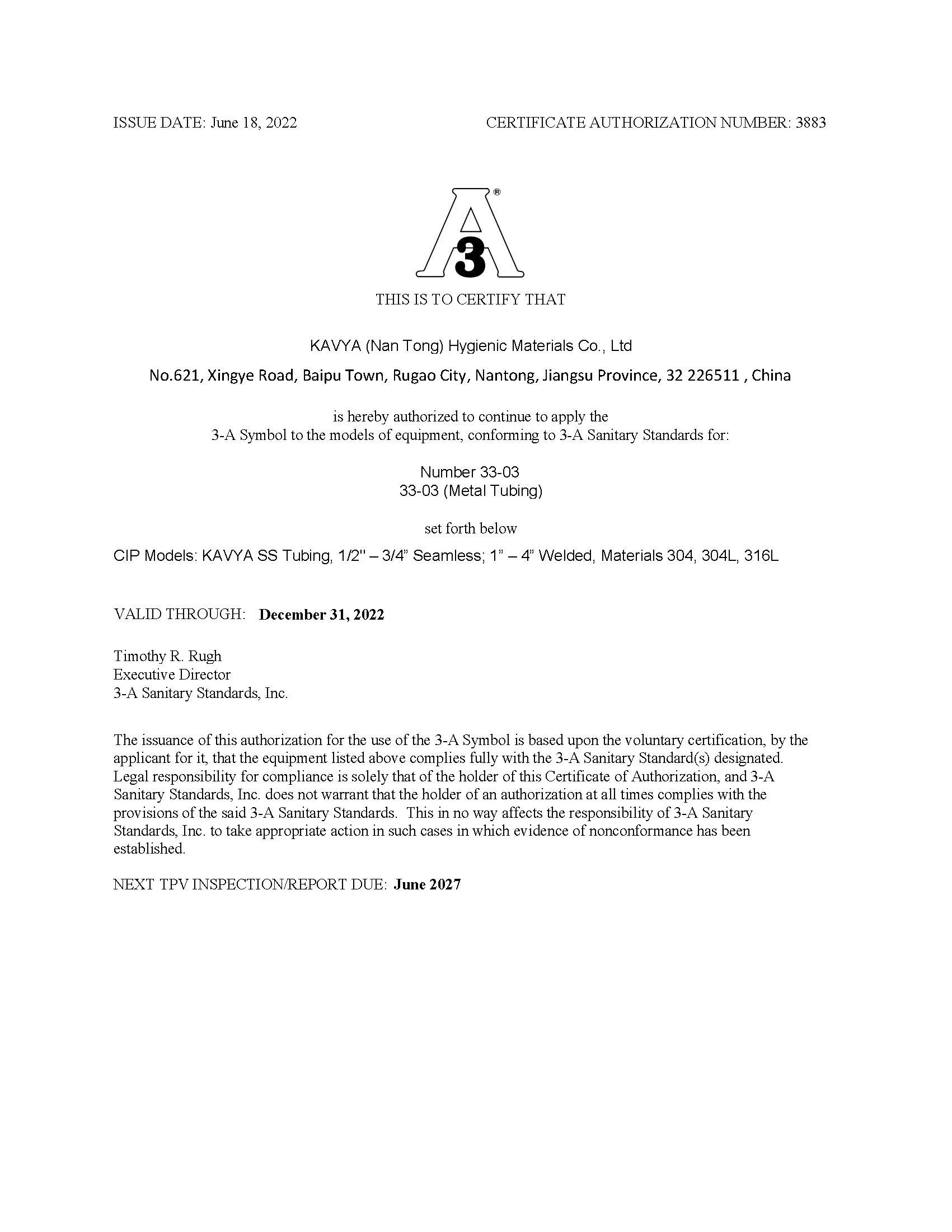

Certificates

At KAVYA, we are proud of our commitment to quality and excellence, which is reflected in our certifications. Our products meet rigorous industry standards, ensuring reliability and performance. We hold certifications such as TS, ASME BPE, 3A, ISO9001, ISO14001, ISO45001 etc., which validate our adherence to international quality and safety standards. These certifications underscore our dedication to delivering superior products and services that exceed customer expectations.

Get a Quote